There are many factors to consider when deciding on a metal joining method, including both tangible and intangible characteristics. Depending on the application, investments will vary based on connection design, welding materials, geometry, size and dimensions, environmental impact, and the mechanical and electrical integrity required for a given product. It is impossible to cover all connection methods in one article, so we will focus on the automotive wiring harness industry to clarify the differences between crimping, soldering, ultrasonic welding, laser welding and resistance welding.

In some cases, ultrasonic welding may seem like the only solution, or it may not be feasible at all. However, no matter how many variables are considered when choosing a joining method, ultrasonic welding appears to offer better long-term returns than all other viable processes.

The initial investment in ultrasonic metal welding equipment is higher relative to other welding processes such as resistance welding, crimping, and mechanical joining, but lower than laser welding equipment. So why is this technology dominating wire harness manufacturing and becoming a necessity for electric and hybrid vehicle batteries and power distribution systems? Ultrasonic welding of non-ferrous metals has been a proven technology for decades. However, ultrasonic metal welding has dominated the automotive industry since the early 1980s, with automotive wiring harness manufacturers being the largest users of this technology (Figure 1). Due to its efficiency and unparalleled quality, ultrasonic welding has replaced mechanical crimping and resistance welding in all car brands almost as soon as it emerged. The use of ultrasonic welding in automotive wiring harnesses has seen even more rapid growth over the past decade due to the increase in electric vehicles (EVs).

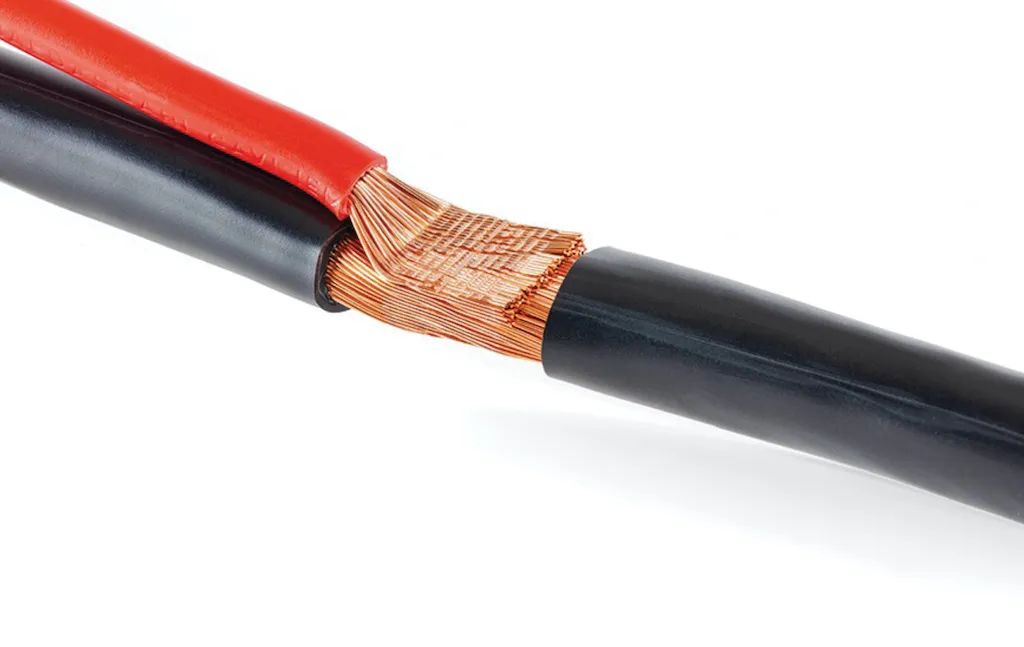

An average vehicle wiring harness contains 180 ultrasonic welded joints, and this number increases with model years. OEMs are adding more electronic features to cars, which requires more connectors. Together, the connectors and wire terminals form a long, complex, heavy-duty wiring harness that controls the entire electrical system throughout the vehicle. Due to the inherent labor intensity of wire processing, wire splicing has been a primary focus of wire harness manufacturing. However, the wire harness industry still uses crimping or resistance welding for applications such as small wire crimping or tin wire splicing. Generally speaking, ultrasonic welding is not feasible for tinned parts or hard materials like steel. This is where resistance welding or laser welding options become viable. However, when it comes to aluminum, which is very popular these days, and when it comes to welding aluminum to another non-ferrous metal, ultrasonic welding is the ultimate choice. Due to its cold fusion welding properties, aluminum can be welded securely without melting or being significantly affected by heat. The benefits of ultrasonic welding apply to thermally conductive materials such as aluminum, copper and magnesium, which can be cumbersome to weld with resistance welders and lasers. Ultrasound is also very useful for joining thin and thick materials.

Ultrasonic is often the best welding process when minimizing thermal interference with material properties is required.

Wire splicing is an excellent example to evaluate some of the joining processes used in today's wire harness manufacturing. Manufacturers have been using the crimping process for years before welding became a viable option. Some OEMs simply use clamps to crimp the wire into the connector. Some are also dipped in a bath of solder to ensure electrical integrity. The disadvantages are the need to add material (many different sized clips), the space required for a dedicated press, the required soldering skills, and the effect on the wire harness due to the mechanical stress and heat generated by the clips and solder.

Therefore, starting with resistance welding and then ultrasonic welding, the welding of wires became very necessary. The cold melt nature of ultrasonic metal welding, its ability to eliminate oxidation before welding, the joining of dissimilar metals, extremely low energy consumption, and the ability to use one machine and the same universal tools to weld a variety of joint sizes are the reasons why ultrasonic metal wire Joints become a convincing factor in globally accepted workmanship. It took several years for wire harness manufacturers to become familiar with the process and adopt the technology. Some switch from crimping to ultrasonic welding, and some use resistance welding before switching to ultrasonic welding. Ultrasonic welding equipment has advantages over other joining methods that still exist today.

The operating/maintenance costs of each joint must be verified simultaneously, but quality is the highest priority. Here are some factors to consider when choosing a connection method:

·Initial investment and quantity

·Output rate

·Consumables

·Power consumption - ultrasonic welding requires 5% of resistance welding

·Additional infrastructure such as water cooling, ventilation and additional electrical installation

·The required floor space for the equipment

·Changes over time

· Setup time for each application

·Mold life and its impact on quality (Figure 2)

Advantages of ultrasonic metal welding

·Low temperature process does not affect material properties

·Pure metallurgical bonding agent suitable for a variety of non-ferrous metal materials

·Ability to weld dissimilar materials

·No consumable materials such as connector clips or solder

·Environmentally friendly technology

·Consistent welding quality, mechanical and electrical performance

·Fast cycle times

·Friendly human-computer interface

·No smoke or chemicals such as lead to ensure operator safety

·process

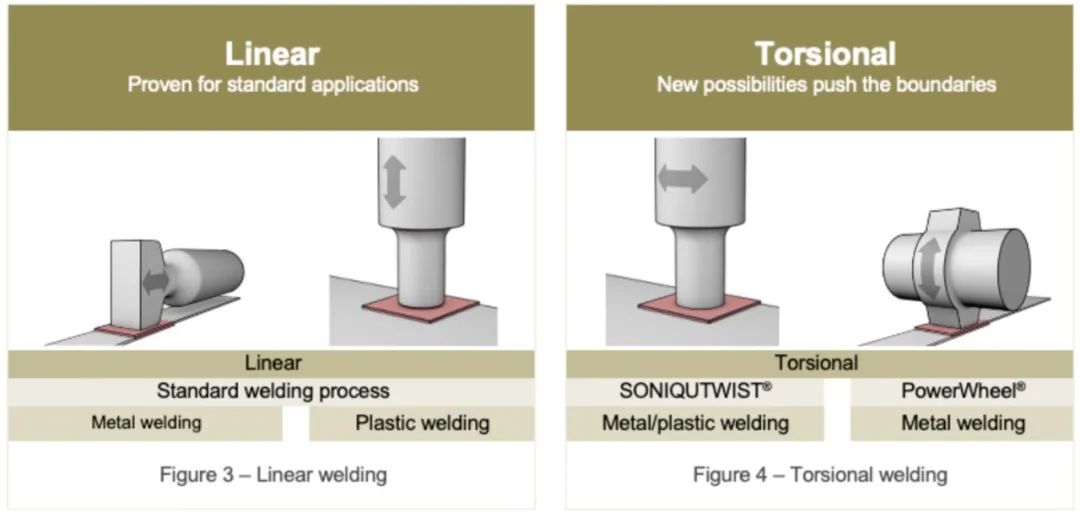

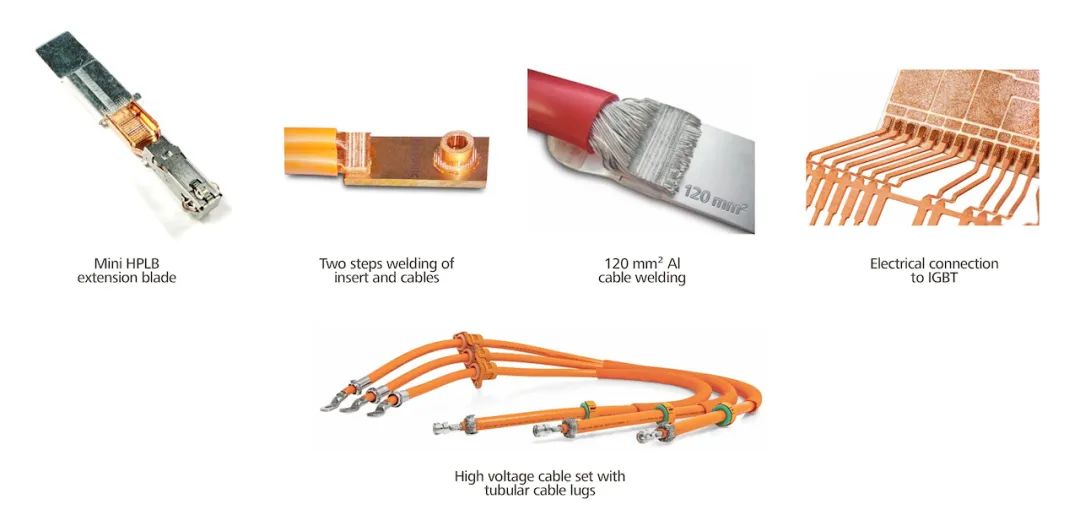

There are two types of ultrasonic welding methods: metal and plastic. Linear soldering is the more common technique used by equipment manufacturers and is the standard for wire splicing (Figure 3). Twist welding technology can be used for most common applications of linear welding. However, due to its unique features, it has certain advantages in terms of applied geometry and gentle process, leading to wider applications in the market. In fact, this technology is sometimes found to be the only solution for electric vehicle battery manufacturers and high-voltage cable welding (Figure 4). Other examples where torsional ultrasonic welding has proven to be a superior method include busbars, 3D terminals, and integrated gate bipolar transistors (IGBTs).

Ultrasonic welding technology

Examples of current ultrasonic welding electric vehicle applications

working principle:

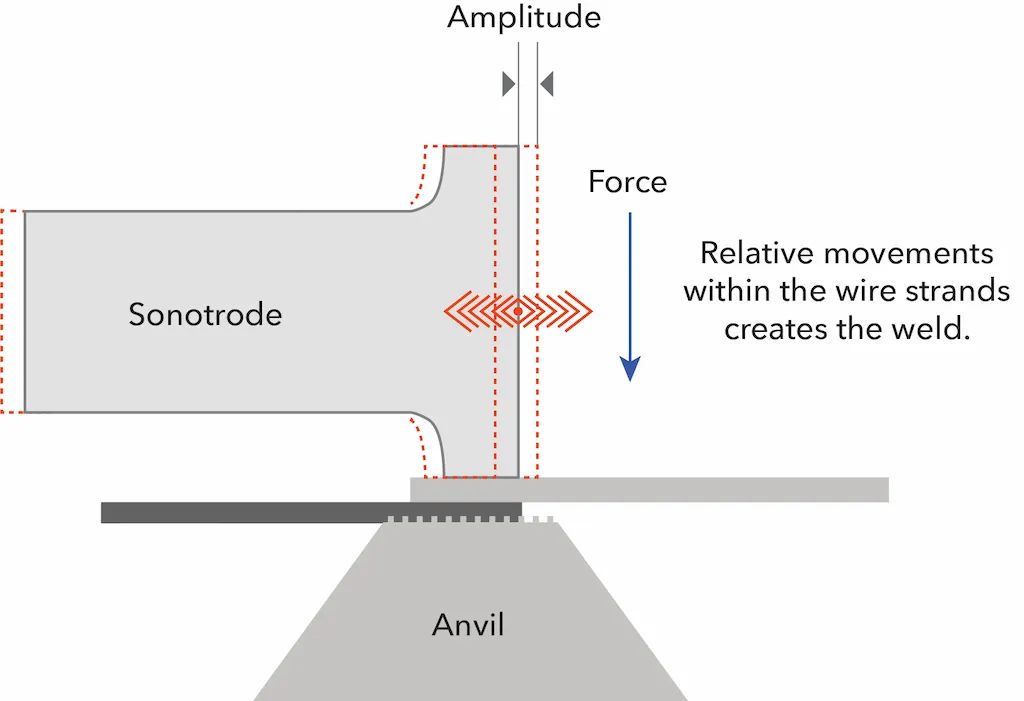

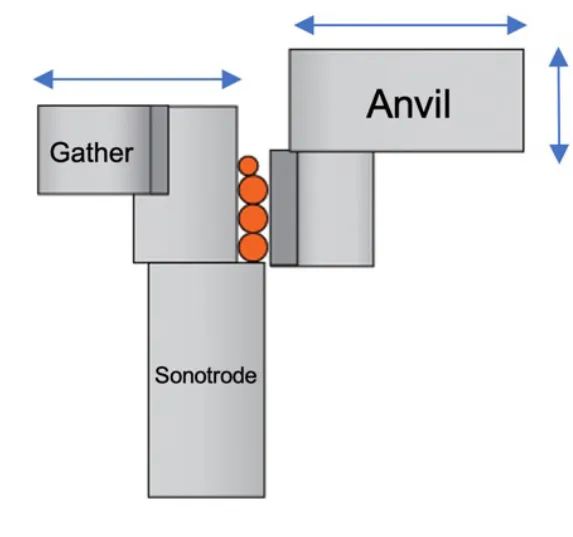

The wire is stacked between the vibrating/oscillating tool (ultrasonic generator) and the anvil. They are confined within a predetermined space before static force is applied via the anvil. As oscillations occur, the metal surface heats up and plasticizes, and the strands bond together by mixing with each other at the molecular level (Figure 6). The result is a continuous weld with a fine-grained structure, similar to that of cold-worked metals. The entire process is very fast, with welding typically completed in less than a second

The most common fusion splicers in use today operate on mechanical vibration at a frequency of 20KHz. The vibrations under the force dissipate any contaminants and initiate cold friction welding until the weld is complete. Due to the friction at the welding interface, the temperature rise of the welding material is less than 30%. Therefore, there is no wire hardening that would make the strands brittle in the weld transition zone. This is one of the many advantages over resistance welding, which often melts material to form a nugget.